Backflow prevention testing: 2025 Ultimate Safety Guide

Why Backflow Prevention Testing Protects Your Water and Your Community

Backflow prevention testing is a mandatory annual inspection ensuring that devices protecting your drinking water from contamination are working correctly. It is legally required for commercial properties, irrigation systems, and certain residential setups to prevent harmful substances from flowing back into the public water supply.

Here’s what you need to know:

- What it is: Testing of mechanical valves that stop contaminated water from reversing into clean water lines.

- Who needs it: Commercial buildings, irrigation systems, fire protection systems, and multi-unit residential properties.

- How often: Annually at minimum, plus after installation, repairs, or relocation.

- Who can test: Only certified backflow prevention testers with proper credentials.

- Consequences: Fines from $58-$1,500, water shut-off warnings, or complete service disconnection for non-compliance.

- Why it matters: A single backflow incident can contaminate water for an entire community.

In 2005, a car wash contaminated the water supply for 30,000 residents in Stratford, Ontario. This incident could have been prevented with a properly functioning backflow prevention device.

Backflow is the reversal of water flow from a property back into the public system. This reversal can pull in chemicals, fertilizers, or other contaminants, posing serious health risks. For example, a garden hose submerged in a bucket of fertilizer creates a cross-connection. During a pressure drop (like when firefighters use a hydrant), that contaminated water can be siphoned into your neighborhood’s drinking water.

Mechanical backflow prevention devices act as one-way gates, but they can wear out or fail. That’s why testing is a public health mandate, not an option.

This guide covers what property owners in Riverside and the Inland Empire need to know about backflow testing, including procedures, qualifications, and the importance of compliance for community water safety.

The Dangers of Backflow: Understanding the Threat to Your Water

Backflow prevention testing exists to prevent a dangerous scenario: contaminated water coming from your tap. Backflow is the reverse flow of water from your property into the public supply. This can send contaminants like fertilizers, pesticides, or chemicals into your neighbor’s drinking water.

The cause is often a cross-connection—an unwanted link between clean water and a source of contamination. Common examples include a garden hose left in a bucket of soapy water or an unprotected irrigation system. These seemingly innocent setups create pathways for contamination.

The United States Environmental Protection Agency’s Cross-Connection Control Manual provides detailed guidance on preventing these vulnerabilities. Regular backflow prevention testing ensures these connections never become contamination highways.

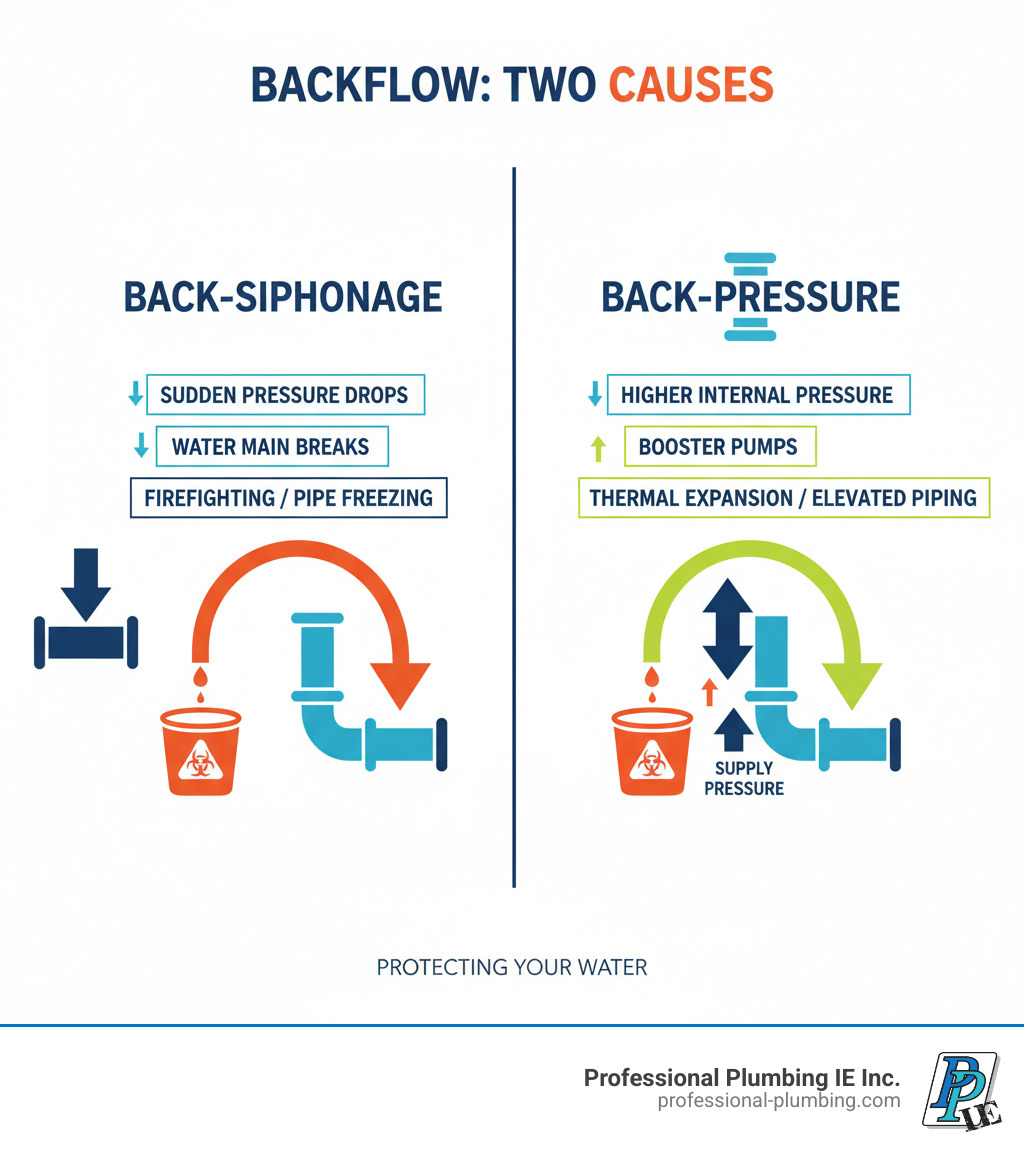

Primary Causes of Backflow

Backflow is triggered by two main conditions.

Back-siphonage occurs when a sudden pressure drop in the public water supply creates a vacuum, pulling water backward from your property. Common causes include water main breaks, firefighting operations, and pipe freezing.

Back-pressure is the opposite: water is pushed into the public supply because your property’s plumbing pressure is higher than the city’s. This can be caused by booster pumps, thermal expansion from water heaters, or lifted piping that creates higher internal pressure.

Both scenarios are serious threats, which is why backflow prevention testing is legally required to catch these problems before they cause contamination.

Property Types and Their Specific Risks

Different properties face different backflow risks.

For residential properties, the main risks are irrigation systems (due to fertilizers and pesticides), swimming pools, and even a simple hose bib connected to a chemical sprayer. Most cities in Riverside and Orange County require backflow preventers on irrigation lines. While most single-family homes don’t need annual testing unless they have these high-risk connections, it becomes mandatory if they do. Learn more on our Residential Plumbing Services page.

Commercial properties have higher risks. Restaurants have grease traps, medical offices use chemical sterilizers, and car washes use strong detergents. These potential contamination pathways mean annual backflow prevention testing is the law.

Industrial facilities are the highest-risk category, requiring robust prevention and frequent testing due to chemicals, high-temperature processes, and complex piping.

Fire protection systems are also a concern. Water in sprinkler lines can become stagnant and corrosive, sometimes containing chemical additives. If this water backflows, it’s a health hazard. Fire codes often require specific devices, like a Reduced Pressure Zone Assembly, for these systems.

Our team has handled commercial backflow testing throughout Riverside for nearly 40 years. Learn more about how we keep businesses compliant on our Commercial Plumbing Services page.

Backflow Prevention Devices: Your System’s Shield

Backflow prevention devices are mechanical safeguards that act as a physical barrier, stopping contaminated water from flowing backward into the clean supply. The right device for your property depends on its hazard level assessment—how dangerous the potential contamination is.

Local plumbing codes and fire codes in Orange County and Riverside specify which devices are legally required for different situations. Our backflow prevention testing verifies these devices are working correctly. For more on our comprehensive plumbing solutions, see our Our Services page.

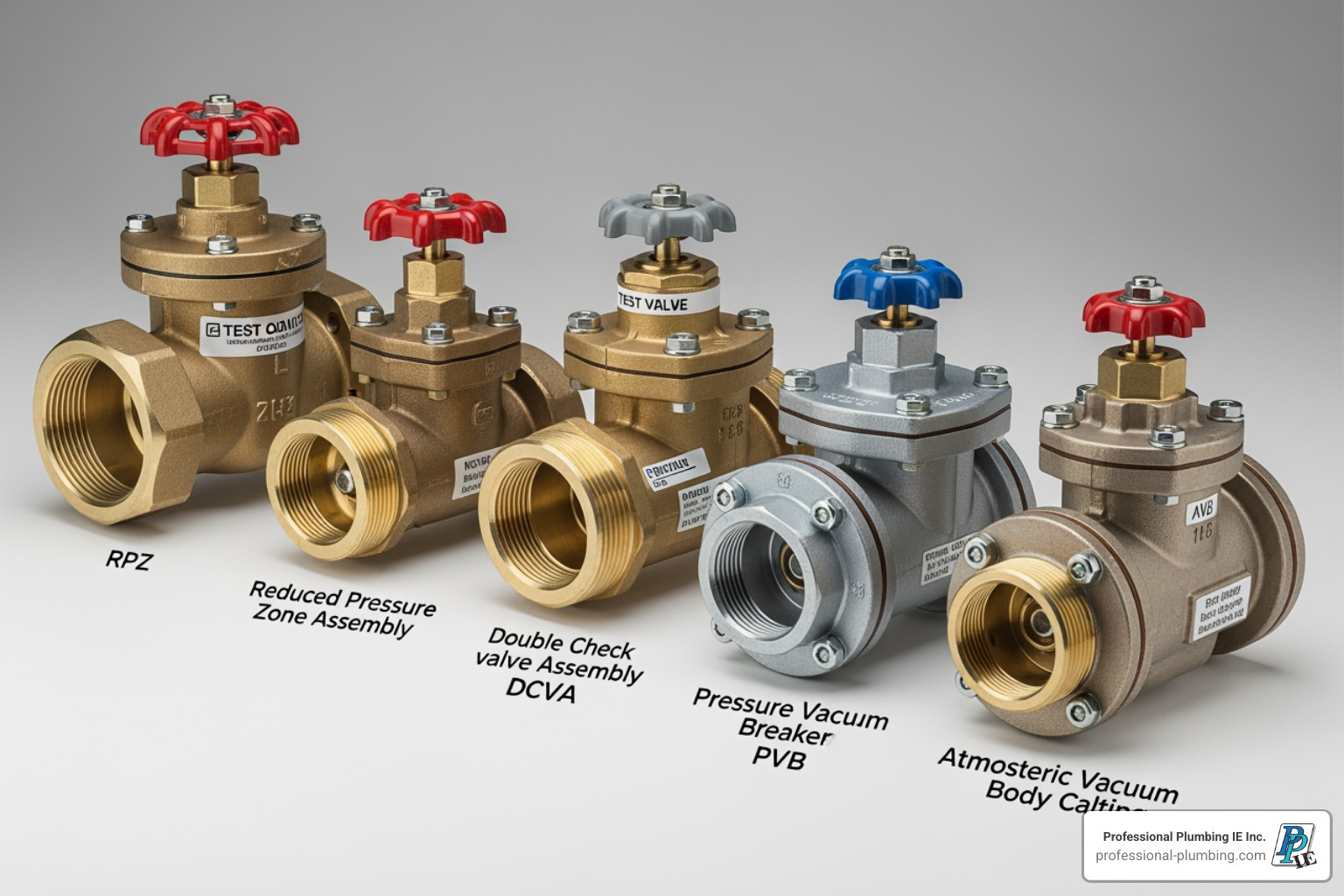

Types of Backflow Prevention Assemblies

Here are the most common types of backflow preventers.

The Reduced Pressure Zone Assembly (RPZA) offers the highest level of protection against both back-siphonage and back-pressure. It has two independent check valves and a relief valve in between. If a check valve fails, the relief valve discharges water, preventing backflow. RPZAs are required for high-hazard situations like hospitals, industrial sites, and many fire protection systems. Because they can discharge water, they must be installed where drainage will not cause damage.

The Double Check Valve Assembly (DCVA) is used for moderate to low-hazard situations. It has two check valves to protect against back-siphonage and back-pressure but lacks a relief valve, so it doesn’t discharge water. It’s common for residential irrigation systems and some commercial buildings.

The Pressure Vacuum Breaker (PVB) protects against back-siphonage only. It uses a check valve and an air inlet that opens to break a vacuum. PVBs are common for irrigation but must be installed at least 12 inches above the highest point of the system. They can discharge water and are not for continuous pressure applications.

Finally, the Air Gap is the simplest method: an unobstructed vertical space between the water supply outlet and the flood level of a container (like the gap between a faucet and sink). Contaminated water cannot jump this gap, making it foolproof for high-risk applications like filling tanks.

The Essentials of Backflow Prevention Testing

Backflow prevention devices have mechanical parts that can wear out, get clogged, or fail over time. A failed device is a liability. Therefore, regular backflow prevention testing is essential to ensure these devices are working correctly, protecting public health and maintaining regulatory compliance.

Why is Regular Backflow Prevention Testing Necessary?

These devices operate under constant pressure and can fail. As the American Backflow Prevention Association notes, regular testing is necessary for several key reasons:

- Annual Requirement: Most municipalities, including those in Orange County and Riverside, mandate annual backflow prevention testing.

- Post-Installation Testing: A new device must be tested immediately after installation to confirm it works correctly.

- Post-Repair Testing: A device must be re-tested after any repair or maintenance to verify the fix was successful.

- Manufacturer Recommendations: Manufacturers often specify testing schedules to maintain warranties and ensure performance.

- Municipal Codes: Local codes are the final authority on testing frequency and reporting protocols.

The Key Procedures for Backflow Prevention Testing

Here’s what to expect during your backflow prevention testing:

- Initial Assessment: Our technician locates the assembly, verifies its type, and checks for visible damage and accessible shut-off valves.

- Temporary Water Shut-off: The water supply to the device is shut off for about 30 minutes to perform the test safely and accurately.

- Connecting the Test Kit: A specialized, calibrated test kit with pressure gauges is connected to the device’s test cocks to measure pressure differentials.

- Pressure Differential Readings: By operating valves, we observe pressure readings to ensure check valves hold pressure and relief valves (on RPZAs) function to spec.

- Valve Operation Check: We verify that check valves seal tightly and that RPZA relief valves open and discharge water at the correct pressure.

- Test Report Documentation: After restoring water, we complete a detailed test report with the results and device information. This official document is then submitted to your local water authority to certify compliance.

This thorough process ensures your backflow prevention device is an effective barrier, protecting your water and our community.

Compliance, Certifications, and Consequences

Protecting community water is a shared responsibility, but the property owner is legally responsible for ensuring their backflow prevention device is tested and maintained per local regulations. Water authorities in Riverside, Orange County, Corona, and Fountain Valley enforce these rules to keep the public safe from water contamination.

Skipping your annual backflow prevention testing leads to escalating consequences, starting with warning tags (around $58) and leading to fines up to $1,500. Your water service can be shut off until you comply—a major disruption for any home or business.

Who Can Perform a Backflow Test?

Not just any plumber can perform this test. It is specialized work requiring specific training, certification, and equipment.

Testers must hold current certifications from organizations like the American Society of Sanitary Engineering (ASSE) or the American Backflow Prevention Association (ABPA). These programs ensure testers understand the science and public health importance of backflow prevention. Testers must also meet state and local requirements, which can vary by jurisdiction. Our technicians hold all necessary certifications for our service areas.

Finally, the test equipment itself must be calibrated annually to ensure accurate readings. Our test kits are properly maintained and calibrated, as precision is critical for public health.

What Happens if a Device Fails a Test?

A failed test isn’t a disaster; it means the inspection process is working by catching a problem before it becomes a hazard.

If your device fails, our tester will notify you immediately, explain the problem, and recommend either repair or replacement. Most jurisdictions provide a compliance window (often 15 days) for this work. This quick turnaround is necessary because a failed device poses an immediate risk to the public water supply.

After repair or replacement, the device must be re-tested to confirm it is functioning correctly. This step is mandatory. Once the device passes the re-test, we submit the passing report to the water authority to clear your non-compliance status. Our team handles this entire process for you, from diagnosis and repair to re-testing and submitting all required documentation.

Frequently Asked Questions about Backflow Prevention

Here are answers to the most common questions we receive about backflow prevention testing.

How often should backflow prevention devices be tested?

The standard requirement is once a year. Annual testing is mandated by most municipalities in our service areas, including Orange County, Riverside, Corona, and Fountain Valley. Testing is also required immediately after installation, after any repairs or maintenance, and if the device is relocated. Your local water authority has the final say on deadlines and enforcement, so always check their specific requirements or contact us for guidance.

Who is responsible for ensuring backflow testing is done?

The property owner is legally responsible. This includes scheduling the test with a certified tester, covering all costs (including potential repairs), and ensuring the test report is submitted to the water authority on time. Missing the deadline can lead to fines or water shut-off. A reliable plumbing partner like us can make this process routine by handling the testing, paperwork, and submissions for you.

Do I need a backflow preventer for my lawn irrigation system?

Yes. Irrigation systems are considered high-hazard cross-connections. Water in these lines can be contaminated with fertilizers and pesticides. During a pressure drop in the main water line, this contaminated water can be siphoned back into the drinking water supply. For this reason, nearly all Southern California municipalities mandate an approved, regularly tested backflow prevention device on all irrigation systems. If you’re unsure about your system’s compliance, contact us for an inspection.

Protect Your Water, Ensure Your Compliance

As this guide has shown, backflow prevention testing is more than a compliance task; it’s a critical safeguard for our community’s clean drinking water. A single preventable backflow event can endanger thousands, a reality we work to avoid in Riverside, Orange County, Corona, and Fountain Valley.

While avoiding fines (from $58 to $1,500) and water shut-off is important, the real goal is peace of mind. Compliance ensures your water is safe, your business is not at risk, and you are protecting public health.

As a family-owned business with nearly 40 years of experience, Professional Plumbing IE Inc. is dedicated to serving our community. Our certified technicians understand local regulations and work efficiently to provide thorough, accurate testing with minimal disruption. We offer professional, guaranteed quality service at affordable rates because we believe protecting your water should be accessible.

Be proactive—don’t wait for a warning notice. Whether you’re a homeowner, business owner, or property manager, we can help you stay compliant and keep your water safe.

Contact Us for certified backflow prevention testing today to schedule your inspection. Let’s work together to protect what matters most.